Introduction to Process Safety Reviews

We have a wealth of experience in facilitating comprehensive safety studies such as HAZID, What-if?, HAZOP, SIL determination (e.g. Layer of Protection Analysis or LOPA)) and Inherently Safer Design (ISD) reviews.

Leading such studies requires not only sound technical knowledge, but also good leadership skills. At Safety Engineering Solutions, we have both. See below for more detail on each.

HAZID & HIRA

Hazard Identification (HAZID) studies are typically conducted early-on in the design phase of a project to elicit the major accident hazards (MAHs). The HAZID is kept up to date for operational facilities and so is reviewed and updated periodically to ensure any changes to the organisation (people), procedures or equipment (plant) are considered as part of the management of change process.

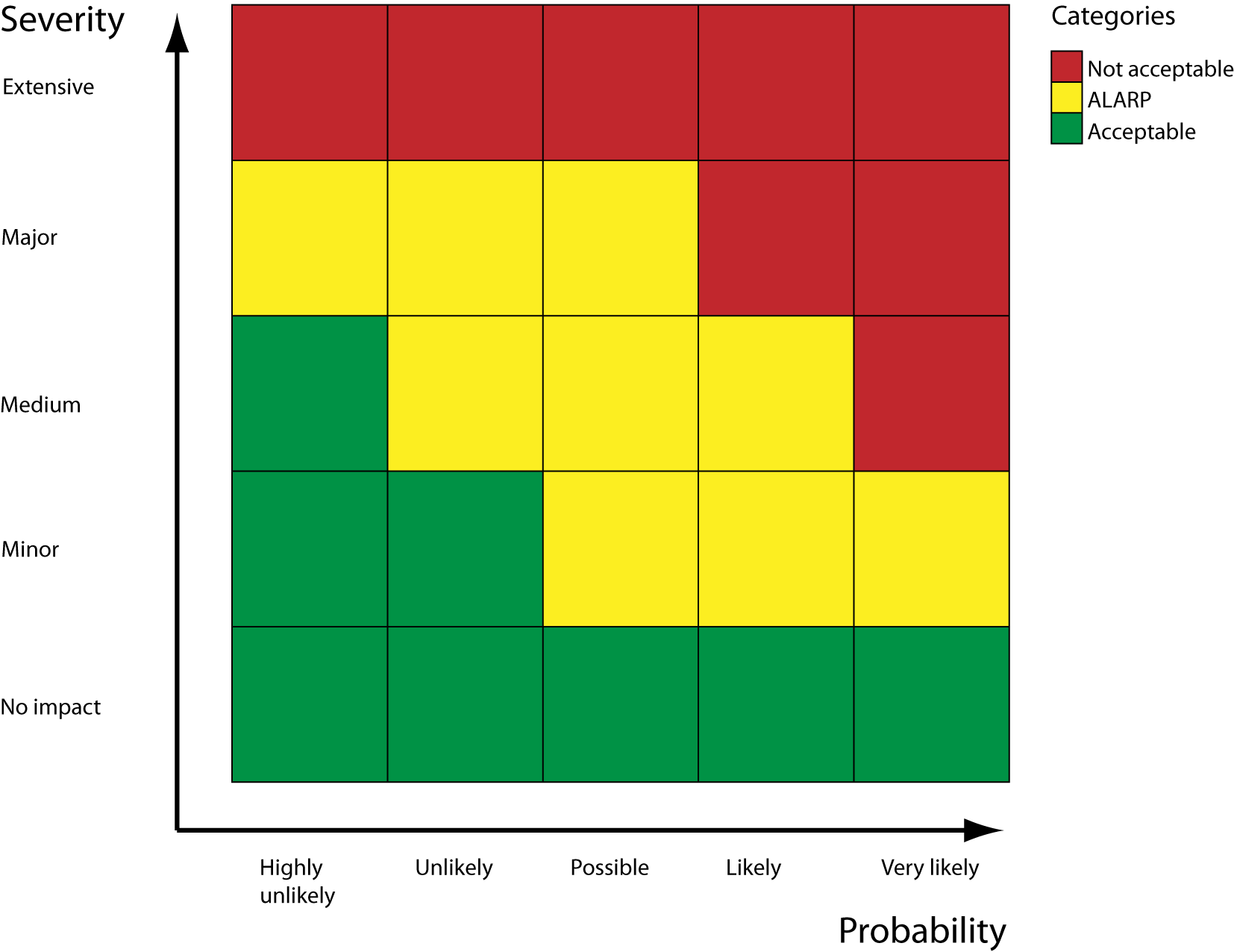

When risks are assessed, the assessment becomes a hazard identification and risk assessment (HIRA) exercise. The HIRA technqiue is also used in the assesment of Simultaneous Operations (SIMOPS) and we have meaningful experience of such studies, including the development of SIMOPS matrices of permitted operations (MOPO).

Our facilitators are all IChemE trained with a wealth of experience in different industries. We manage the whole process from developing terms of reference, developing risk tolerance criteria (risk matrix) as required, through to management of study actions, if required. Using PHA Pro to record the review allows for the capture of efficiencies, thereby saving assessment time. We can also provide a technical scribe.

Hazard and Operability (HAZOP) Study

A Hazard and Operability study - or HAZOP for short - is an industry standard technique, a team-based assessment of a process using a structured methodology to brainstorm the causes of deviations from normal operating conditions.

Our facilitators are IChemE trained with a wealth of experience in different industries any apply current best industry practice. We manage the whole process from develping terms of reference, through to management of HAZOP workshop actions.

Using PHA Pro to record the review allows for the capture of efficiencies, thereby saving assessment time. We can also provide a technical scribe. Depending on the scope of the HAZOP study, the Chairman can also perform the dual role of chairing and scribing.

SIL Determination & SIL Verification

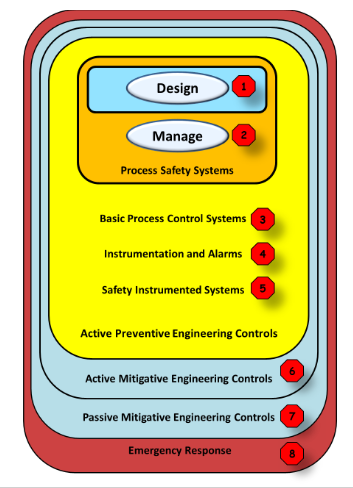

Applying the well-known principles of IEC 61508/61511, we can lead Safety Integrity Level (SIL) assessments using methodologies such as Safety Layer Matrix, Risk Graph and Layers of Protection Analysis (LOPA).

The session can be recorded using standard software such as Word and Excel or a more efficient means such as PHA Pro which allows the output from a HAZOP study to be automatically transferred into the SIL assessment, thereby saving time. A LOPA workshop can also be conducted in Bowtie diagram format using CGE risk’s Bowtie XP software which allows for a more visual-based, engaging assessment.

See link to SIL workshop / LOPA study Chairman / Risk Graph Facilitator credentials. Our study leaders are Functional Safety Expert certified.

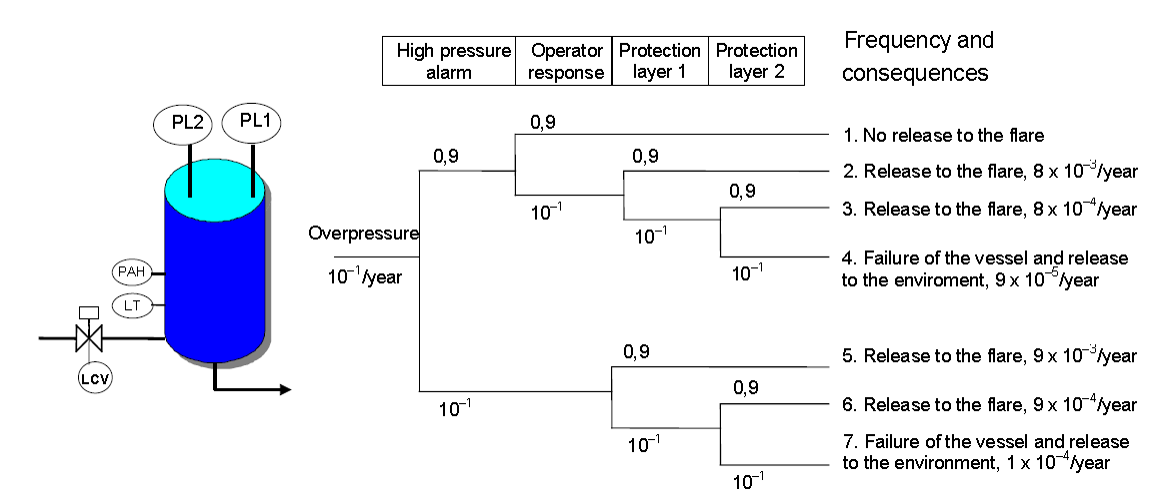

Layers of Protection Analysis (LOPA)

LOPA is an industry standard technique, a team-based assessment of a process using a structured methodology to assign a safety integrity level to a safety instrumented function (SIF).

Our primary LOPA Chairman is Alastair Millard - IChemE trained and a TUV certified Functional Safety Engineer with a wealth of experience in different industries. The LOPA study leader can manage the whole process from developing the terms of reference, developing SIL risk tolerance criteria, through to management of LOPA workshop actions.

Using PHA Pro, ExSILentia (or other software of your choice) to record the review allows for the capture of efficiencies, thereby saving assessment time.

The LOPA Study Leader can also provide a technical scribe, if required.

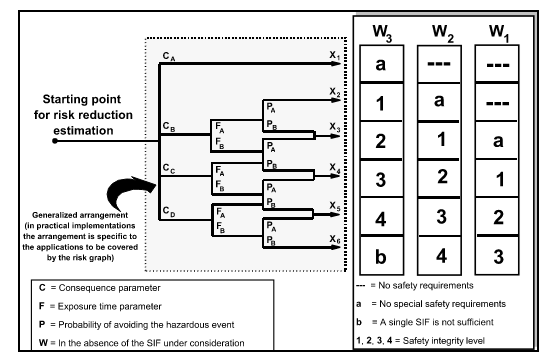

Risk Graph

Risk Graph is an industry standard technique, a team-based assessment of a process using a structured methodology to assign a safety integrity level to a safety instrumented function (SIF).

Our primary Risk Graph Facilitator is Alastair Millard - IChemE trained and TUV certified Functional Safety Engineer with a wealth of experience in different industries.

The Risk Graph study Leader can manage the whole process from developing the terms of reference, through to management of LOPA actions.

Using PHA Pro, ExSILentia (or other software of your choice) to record the review allows for the capture of efficiencies, thereby saving assessment time. The Risk Graph review workshop Chairman can also provide a technical scribe, if required.

SIL Verification

We can provide comprehensive SIL verification services using the powerful software tool, ExSilentia. We can perform SIL verification following SIL determination or as a standalone activity. One benefit of ExSilentia is that the PHA, SIL determination and SIL verification can all be performed in the same software. All our personnel are certified Functional Safety Engineers.

Inherently Safer Design Review

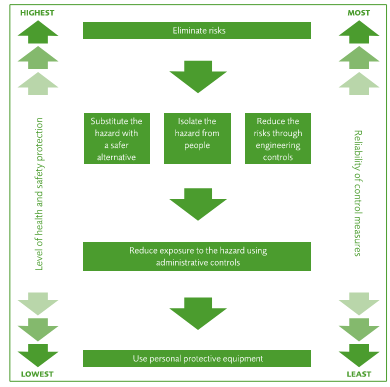

Inherently safer design (ISD) is a philosophy for addressing safety issues in the design and operation of processes. When considering ISD it is attempted to manage process risks by eliminating or significantly reducing hazards. Although the principles of ISD can be applied to a facility at any time, even after it is in operation, it is best used during the early stages of a design. It is at this time that fundamental changes can be made quickly and easily, and most gain is obtained. Once detailed design is underway, such changes are harder to make, and they become even harder as a project enters the procurement, construction, and commissioning phases.

The goal of ISD is to assess whether potential Health, Safety & Environment (HSE) hazards can be eliminated completely or reduced in severity.

The strategy in accomplishing ISD objectives is to eliminate, minimize, substitute, moderate and/or simplify, for example:

Eliminate: Find an alternate option that eliminates the hazard altogether

Minimize: Use smaller quantities of hazardous substances / smaller storage inventory

Substitute: Replace material or equipment with less hazardous substance or characteristics

Moderate: Use less hazardous conditions, a less hazardous form of a material, or facilities which minimize the impact of a release of hazardous material or energy

Simplify: Design facilities which eliminate unnecessary complexity, make operating errors less likely, and prevent errors in operations

Projects that consider design, equipment, and technology selection based on these strategies will produce an inherently safer design. Our Inherently Safer Design Review facilitators have a wealth of experience in different industries. We manage the whole process from developing terms of reference, through to management of study actions, if required. We can also provide a technical scribe.

Get In Touch With Us Today

Contact Safety Engineering Solutions today on 07808 889 684 or click the link to find out how we can help you manage risk.