Introduction to Flare and Vent Radiation, Dispersion and Noise Modelling

Flare and process vent design requires careful consideration of hazard and risk factors such as thermal radiation, flammables dispersion and noise. These parameters are required to be assessed to define adequate stack height, separation from adjacent facilities and to define any sterile zone.

At Safety Engineering solutions, we have solid experience of flare and vent design using state of the art software such as Flaresim and Phast.

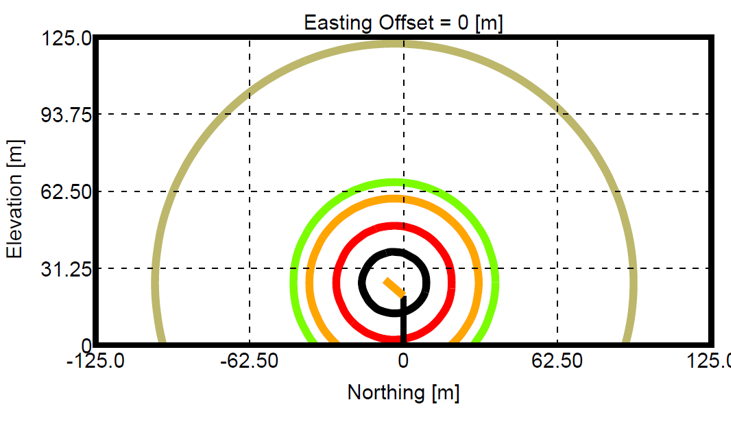

Thermal Radiation Modelling

Flares produce significant amounts of heat, and poorly-designed flares present a danger to people working nearby. We use the proven Flaresim software to design the optimum flare height, the necessary sterile zone, and the separation from adjacent plant.

Flare location and height are important design parameters to firm-up early in the design process as the flare can have a significant impact on facility siting considerations.

Sensitivity analyses are performed to ensure variables are properly considered, thus ensuring a robust assessment.

Safety Engineering Solutions have performed many flare and vent radiation assessments to date.

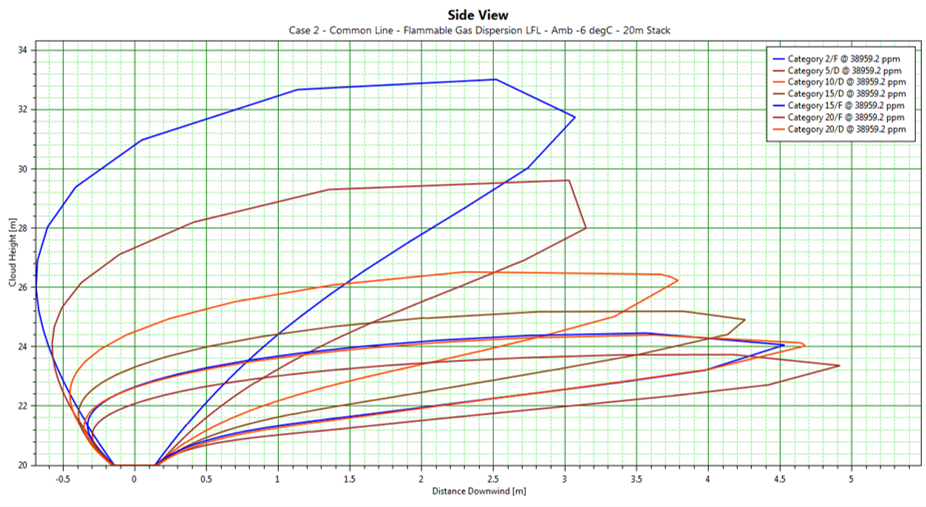

Dispersion Modelling

Adequate dispersion of hazardous vapours from flares and vents is a common requirement. We use Phast software to conduct robust dispersion modelling to define the hazardous area zone extent of any flammable components in line with BS EN 60079 and API RP 505.

Dispersion from flare flame out (e.g., Methane / hydrogen sulphide) or from combustion products (e.g., sulphur dioxide) can be a governing design factor for the flare height and location. Often, reliance on standard look-up tables from industry guides such as EI 15 is not sufficient, especially for complex situations and multi-component mixtures.

Safety Engineering Solutions has the in-house expertise to build the necessary dispersion models and make sense of the results.

Noise Modelling

Flares and vents are inherently noisy. Assessment of noise is an important consideration which should not be left to chance.

We use Schlumberger’s Flaresim software to perform noise modelling of the flare or vent and validate our findings with design vendor information.

Noise modelling conducted early-on in the design process helps the design team to confirm whether noise is an issue, whether it is a governing factor in flare/vent design and what hearing protection measures might be necessary on site. Noise is both a safety and an environmental consideration. Fence line noise limits may need to be adhered to and this is particularly relevant for flares since they tend to be in remote locations, sometimes nearer to the site boundary than the main equipment.

Contact Safety Engineering Solutions today to find out more

Contact Safety Engineering Solutions today on 07808 889 684 or click the link to find out how we can help you manage risk.